3-Ply butyl rubber tape pipe wrap tape for steel pipeline

Product Description

3-Ply Butyl Rubber Tape Pipe Wrap Tape for steel pipeline

I. Description

3-Ply butyl rubber tape is Cold applied tape coating system for corrosion protection of Oil, Gas, Petrochemical, and Waste

Water underground or overhead pipelines. It is a three-ply cold applied tape with stabilized polyethylene backing and

butyl rubber Adhesive layers on both sides.It is also used as inner-layer tape. It shall be applied by hand or with a

wrapping machine

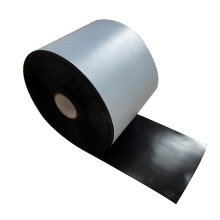

II. Structure

The specification of the 3-Ply butyl rubber tape consists of four layers,

Internal Adhesive layer:Butyl rubber

External Adhesive layer: Butyl rubber

Film backing:Special blend of stabilized polyolefines

Interleaf: Anti-adhesive Film Treated with Silicone

III. Features:

Excellent bonding between adhesive and carrier film via co-extruded intermediate layer.

Mechanically highly resistant tape system.

Practically impermeable to water vapor and oxygen.

Resistant to soil bacterial and soil electrolyte.

Compatible with coating from PE,PP,FBE,PU,CTE and Bitumen and ext…

A Total Coating System with:

High adhesion and shear resistance

Resistance to corrosion disbandment

High electrical resistance

High dielectric strength

High corrosion protection for steel substrates

IV. Physical Properties:

PROPERTIES | UNIT | T 480 | T 4100 | TEST METHOD |

Color Carrie film | -- | black(gray/green) | black(gray/green) | -- |

Thickness Carrie film | mm mm mm | 0.3 0.34 0.16 | 0.3 0.45 0.25 | ASTM D1000 |

Tensile strength | N/cm | 67 | 70 | ASTM D1000 |

Elongation at break | % | ≥450 | 500 | ASTM D1000 |

| Peel strength to pipe surface at 23 ℃ at 50℃ | N/cm |

18 1.3 |

20 1.5 | EN 12068 Annex C |

Peel strength tape to tape at 23 ℃ at 50℃ | N/cm |

25 3.5 |

30 4.0 | EN 12068 Annex B |

Dielectric strength | Kv/mm | 32 | 33.8 | ASTMD149 |

Insulation Resistance | Ohm.m² | 1012 | 1012 | EN 12068 |

Water Vapor Transmission | g/ m2 /24h | 0.1 | 0.1 | ASTM E 96 |

Brittleness temperature | ℃ | -46±4 | -46±4 | DIN53372 |

Water Absorption | % | 0.1 max | 0.1 max | ASTM D 570 |

Impact resistance at 23° | J | 18 | 18 | EN 12068 |

| Cathodic disbandment at 23°c at 50°c | mm | 15 30 | 15 30 |

EN 12068 |

Lap shear strength at 50℃ | N/mm2 | 0.05 | 0.05 | EN 12068 |

V. TAPE - INNERWRAP - CORROSION PROTECTION TAPE

Asymmetrically structured three-ply plastics tape consisting of a stabilized polyethylene backing with plastic butyl rubber on both sides. The consistency of the butyl rubber on the one side facing the pipe surface should be formulated in such a way that, under tension, it flows on uneven steel surfaces. To facilitate correct application this butyl layer should be of a black color. The gray butyl layer of the tape must face the steel and this should always be the thicker layer of butyl rubber.

In order to avoid delaminating tape must contain co-extruded intermediate layers.

The tape must be fully compatible with the properties of the primer. The tape must be self-amalgamating between the layers and at the overlaps and must have a release paper or film.

VI. TAPE - OUTERWRAP - MECHANICAL PROTECTION TAPE

Two-ply plastics tape consisting of a stabilized high density polyethylene backing with plastic butyl rubber on one side. The outer wrap tape must be fully compatible with the properties of the inner wrap. The outer wrap must fully self-amalgamate with the inner wrap tape at contact areas.

In order to avoid delaminating between carrier film and butyl rubber, tape should contain co-extruded intermediate layers.

Packaging : The tape are packaged in cartons

Commonly use carton:

| Tape Thickness | Tape Size | Carton Size | SQM/CTN(m²) | Quantity/CTN |

| 0.51mm | 0.51mm*200mm*50m | 410cm*210cm*415cm | 40 | 4 |

| 0.51mm*150mm*50m | 420cm*420cm*320cm | 60 | 8 | |

| 0.51mm*100mm*50m | 420cm*420cm*320cm | 60 | 12 | |

| 0.51mm*75mm*50m | 420cm*420cm*320cm | 60 | 16 | |

| 0.51mm*50mm*50m | 420cm*420cm*320cm | 60 | 24 | |

| 0.75mm | 0.75mm*200mm*50m | 410cm*210cm*415cm | 28 | 4 |

| 0.75mm*150mm*50m | 420cm*420cm*320cm | 42 | 8 | |

| 0.75mm*100mm*50m | 420cm*420cm*320cm | 42 | 12 | |

| 0.75mm*75mm*50m | 420cm*420cm*320cm | 42 | 16 | |

| 0.75mm*50mm*50m | 420cm*420cm*320cm | 42 | 24 |

Shipping: The tape will be shipped after 7 days of payment(depend on the order quantity)

Container Specification :

| Container Specification | Length*Width*High(m) | Weight (Ton) | Volume (m²) |

| 20GP | Inside: 5.898×2.352×2.385 Outside: 6.058×2.438×2.591 | 17.5 | 33.1(Nomal 28) |

| 40GP | Inside: 12.032×2.352×2.385 Outside: 12.192×2.438×2.591 | 22 | 33.1(Nomal 28) |

| 40HQ | Inside: 12.032×2.352×2.385 Outside: 12.192×2.438×2.591 | 22 | 76.2(Normal 68) |

| 45HQ | Inside : 13.556×2.352×2.698 Outside: 13.716×2.438×2.896 | 29 | 86 (Normal 78) |

Copy to browser:

Jining Xunda Pipe Coating Materials Co.,Ltd , a joint -stock enterprise, possessing a gross investment RMB 42 million, registered capital of RMB 20 million,the manufacturer of anti-corrosion and waterproof coating materials for petrochemical,Oil,Gas and Water underground, underwater and overhead pipelines transport system, are widely used for electricity, chemicals, construction.

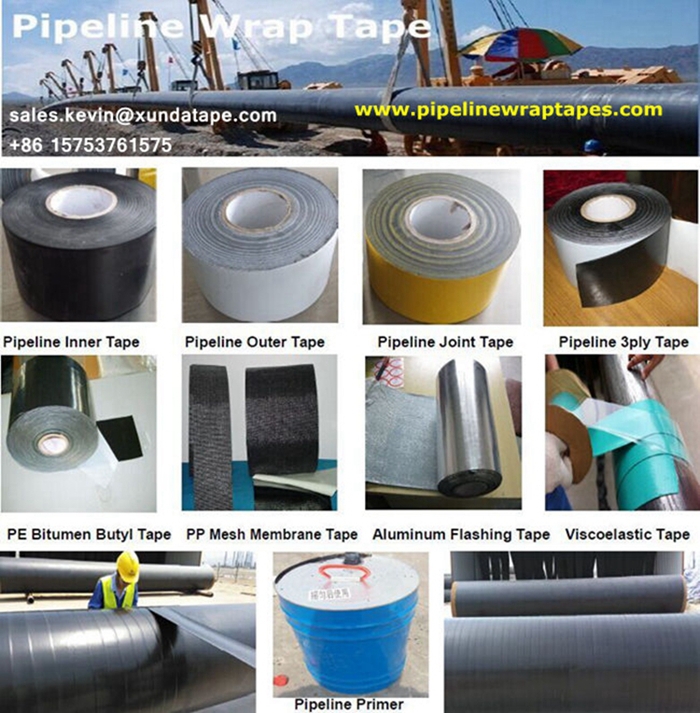

Our main anti-corrosion products : Polyethylene Self Adhesive Tape, Polyethylene Outer Protection Tape, Polyethylene Joint Repair Tape, Polyethylene Double Side Wrap Tape, Polypropylene Mesh Membrane Tape, Polypropylene Waterproof Tape, Aluminum Foil Waterproof Tape, Viscoelastic Body Adhesive Tape, Heat Shrinkable Tape, Heat Shrinkable Sleeve ,Petrolatum Tape etc.

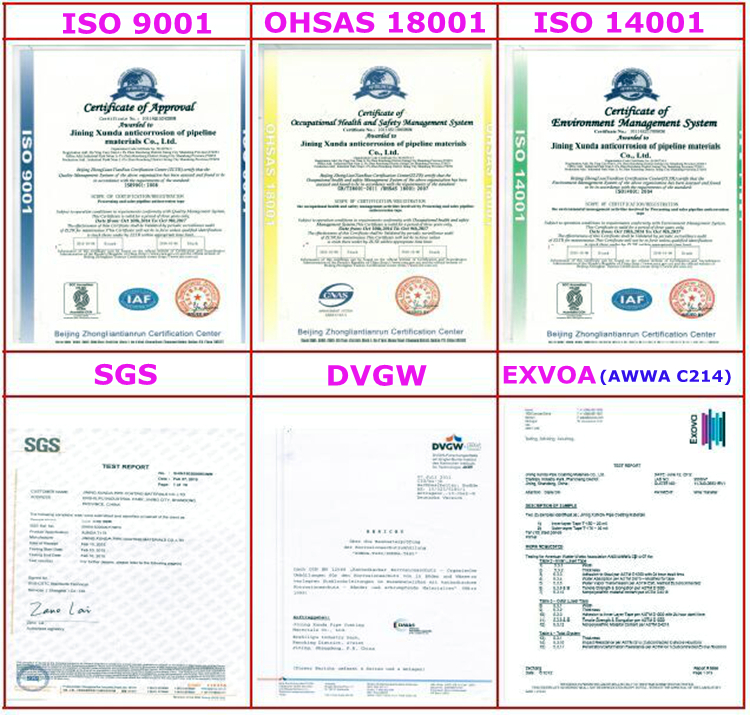

We have got DVGW,AWWA,ASTM,SGS certificates and test report, also the sole factory in China passed DVGW, AWWA test. We were approved ISO 9001,ISO 14001 and OHSAS 18001. XUNDA tapes can meet ASTM D1000, DIN EN12068, 30672,AWWA C209, 214 , IGS and other international standards.

Our major market including 80 countries, widely distributed in South Asia,Southeast Asia, the Middle East, Africa, Central Asia, West Asia, Europe, Eastern Europe, South America, Australia.

Company overview

Our Pipe Wrap tape certificate:

1. ISO 9001

2. OHSAS 18001

3. ISO 14001

4. SGS

5. DVGW

6. EXVOA - AWWA C214

7. SINOPEC : China Petro-Chemical Corporation Supplier

8. CNPC: China National Petroleum Corporation Supplier

9. CNOOC : China National Offshore Oil Corporation Supplier

- 15 years of pipeline coating experience

- Global presence in oil, gas and water industries

- Innovative coatings, high temperature systems and niche coatings with first quality products

- Multiple coating systems to meet end-user applications and requirements

- ISO,AWWA,DVGW,SGS approved manufacturing protocol

- Technology/R&D programs for new products and new processes

- Proven long-term performance and corrosion protection on operating pipelines

- Easy of application, consistent application and lower costs

- Compatible with traditional and current corrosion coatings

- Just-in-Time delivery on a global basis

- Achieving and exceeding Client requirements for products, packaging and shipment expectations

- Meetings all International and In-Country transportation requirements

1. What is the payment terms.

T/T (Telegraphic Transfer) , L/C at sight,Western Union

2. What is the delivery time of the tape.

Usually , 7 days after payment, but it will cost more time when a large order made.

3. Whether the sample is free or not.

The sample will be free with one patch or a small roll . It should paid when you ask for large quantity samples.

4.What is your qualification.

We are the manufacturer of anticorrosion tape for 18 years. All our products are ISO,DVGW, SGS,

AWWA approved.we are the membership supplier of SINOPEC, CNOOC ,CNPC. Our products had

exported to more than 80 countries.

5. What is your after-sales service.

1). Quality reponse

2). Providing technical proposanl and feld application training

3).Product replacement if it is the quality problem.

Product Categories : Butyl Rubber Pipe Coating > Pipe Double Side Adhesive Tape

Premium Related Products