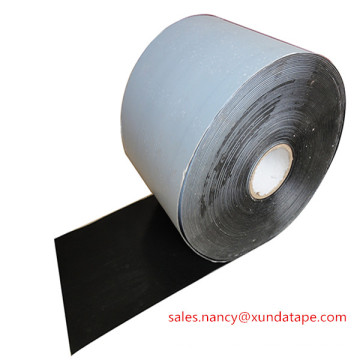

anticorrosion tape with butyl rubber bituminous compound bitumen wrapping tape

Product Description

The XUNDA-T600 series is Cold applied tape Coating System for Corrosion Protection of Oil, Gas, Petrochemical,

Waste Water underground or overhead pipelines and waterproofing.

The Bitumen Tape shall be applied after the primer by hand or with a Wrapping Machine

The specification of the tape consists of three layers,

Adhesive: Butyl rubber Bituminous Compound and Adhesion Promoting Resins

Film backing: Special blend of stabilized polyolefines

Interleaf: Antiadhesive Film Treated with Silicone

Heavy duty butyl bitumen compound adhesive

Excellent adhesion to pipe and self

Flexibility provides extra protection at vulnerable areas

Excellent conformability and consistent uniform thickness

Easily applied with no special equipment

Compatible with common pipe coatings

Excellent resistance to cathodic disbonding

Resistant to UV

Can be applied over a wide temperature range

Good conformability and consistent uniform thickness

Cold applied

PHYSICAL PROPERPTIES | UNIT | TEST METHOD | TYPICAL VALUES | ||||||

Total thickness | mil | ASTM D 1000 | 40mils | 50mils | 60mils | 65mils | |||

Tensile Strength | lb/in | ASTM D 1000 | 30(5kg/cm) | 35(6.3kg/cm) | 39(7kg/cm) | 42(7.5kg/cm) | |||

Elongation | % | ASTM D 1000 | 400 | 400 | 450 | 500 | |||

Length |

|

| 10 m - 100 m | ||||||

Width |

|

| 50 mm-800 mm | ||||||

| Peel adhesion To primed pipe | oz/in | ASTM D 1000 | 269(3kg/cm) | 296(3.3kg/cm) | 314(3.5kg/cm) | 340(3.8kg/cm) | |||

To backing | oz/in | ASTM D 1000 | 90(1kg/cm) | 90(1kg/cm) | 117(1.3kg/cm) | 135(1.5kg/cm) | |||

Dielectric Strength | KV/mm | ASTM D 1000 | 42 | 42.6 | 43 | 43.8 | |||

Volume Resistivity | ohm·m | ASTM D 257 | 2.5 X 1012 | 2.5 X 1012 | 2.5 X 1012 | 2.5 X 1012 | |||

Water Vapor Transmission Rate | g/ m2 /24h | ASTM E 96 | 0.06 | 0.05 | 0.03 | 0.02 | |||

Water Absorptivity | % | ASTM D 570 | 0.1 | 0.1 | 0.1 | 0.1 | |||

Application Temperature | F |

| -31-+160 (-35-+70℃) | ||||||

Max service temperature | F |

| -40-+176 (-40-+80℃) | ||||||

Our hot selling products

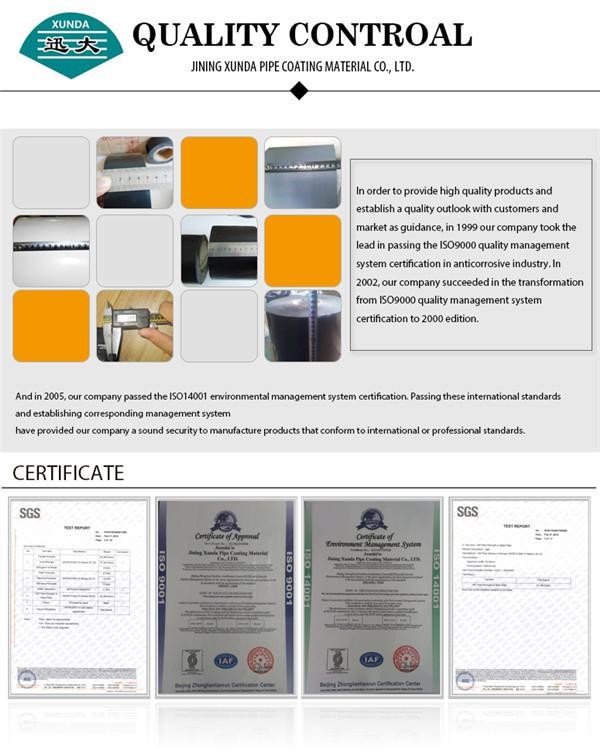

About us

Jining Xunda Pipe Coating Material Co., Ltd. is the largest manufacturer of anti-corrosion coating materials in China.

We are a global company supplying Polyethylene Coating Systems for anti-corrosion in the oil, gas and water pipeline construction industry for both onshore and

offshore applications.

We are a manufacturer of standard and special products. With high-quality anti-corrosion systems, we are providing anti-corrosion solutions for oil pipelines, natural gas, chemicals and water transmission and distribution pipelines. We are a global supplier of PE corrosion systems for metallic pipelines.

We serve:

Oil, gas and water transmission pipeline markets

Oil and gas distribution and utility markets

New pipeline construction markets

Rehabilitation and reconditioning markets

Offshore industry

Refinery and petrochemical plant industry

We manufacture polyethylene coating by utilizing butyl based elastomeric adhesives, Polyethylene

films and liquid adhesives for corrosion protection of steel pipes

TRADE TERMS:

1 Payment: 30% T/T DEPOSIT PAYMENT IN ADVANCE, BALANCE AGAINST COPY OF B/L, WESTERN UNION, ESCROW, L/C.

2 Production Lead Time: 10 - 15 DAYS AFTER DEPOSIT PAYMENT.

3 Shipping Methods: OCEAN FREIGHT / AIR FLIGHT /COURIER PRESS

4 FOB Shipping port: QINGDAO, SHANGHAI ,OTHER PORTS, MAINLAND CHINA.

5 If you want to deal with EXW/CIF/CNF term instead of FOB, please specify. Otherwise, FOB price will be quoted under inquiry.

OUR SERVICE:

- Your inquiry related to our product & price will be replied within 24hours.

- Well-trained & experienced staffs are to answer all your inquiries in English of course.

- Working time: 8:30am - 6:00pm, Monday to Saturday (UTC+8).

- OEM & ODM projects are highly welcomed. We have strong R&D team here to help.

- Your business relationship with us will be confidential to any third party.

- Good after-sale service offered, please get back if you got question.

Transportation and Storage

1) Keep it away from insolation, rain, or pressing.

2) If it has been stored or transported in the temperature below 5degree, it has to be put in the place at about 20degree for 48hours before it is installed.

3) The storage time is 12 months. It should be kept in a cool place at5~30degree, <75degree, away from heat or open fire.

CONTACT US

Nancy Song

Skype:nancysong7

whatsapp:008613791713064

008618853777565

wechat(QQ):438391083

Contact us if you need more details on Bitumen Wrapping Tape. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Butyl Rubber Tape、Anticorrosion Wrap Tape. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Bitumen Pipe Coating > Polyethylene Bitumen Tape

Premium Related Products