Non toxic self healing visco-elastic tape for valve flange fitting anti corrosion

Product Description

Non toxic self healing Visco-elastic tape for valve flange fitting anti corrosion

I. System description:

Visco-elastic Tape is a double sided corrosion preventing wrap material adhering extremely well to steel and factory applied pipeline coating like PE,PP and FBE.

Visco-elastic Tape is a non toxic,cold applied ,visco elastic prefabricated wrap coating,based on a compound consisting of non crystalline, low viscosity, non crosslined .

Visco-elastic tape is a viscous at the indicated operateing temperature.Due to its liquid nature it has a set of unique properties like cold flow into all irregularities of the substrate and self healing of the complete Coating System.The compound does not cure and is unable to resistant to water and has a very low gas and water vapour permeability.

Visco-elastic tape requires application of an additional mechanical protective layer like Xunda Outwrap .This improve impact and indentation resistance of the coating system and supports the self heaking ability of small damages like dent and cuts.

VISCO ELASTIC PASTE

Visco elastic paste is a low temperature ,cold applied ,non crosslinked, non crystalline,monolithic viscous polymer based moulding paste with cold flow ,self healing ,and visco elastic properties.It is a corrosion preventing ,non toxic mouldable material adhering extremely well to steel and factory applied pipeline coatings like PE,PP and FBE.

Visco elastic pasteis viscous at the indicated operating temperature and ,due to its liquid nature,flows into all irregularities of the substrate. The compound does not cure and resistance to water and has a very low gas and water vapour permeability.

II. Product feature:

- Controlled cold flow providing permanent inflow into the finest pores of the substrate

- Resistance to low temperatures without getting brittle

- Conforms to irregular shapes

- Low surface tension,adhereson many types of dry substrates at a molecular level

- constant film thickness

- No osmosis or underfilm migration fo moisture

- No cathodic disbondment

- Inert to ageing and weathering

- Environmentally friendly ,no health and safety hazard to humans

- Rsistant to many chemicals like water ,salts ,acids .alkalis ,polar sovents etc

- Fast and easy to apply

- Easy to control applicaiton

- Surface tolerant no blasting techniques required ,wire brushing is sufficient

- Can be moulded onto various types of irregular shaped objects

- Cathodic protection of steel structures is not affected

- Guaranteed performance

- Piping and Vessels: For proteciton against external corrosion of buried immersed or above ground carbon steel ,alloyed steel and ductile iron pipeline structures and reservoirs

- Field Joint: For protection against external corrosion of buried ,immersed or above ground carbon steel ,alloyed steel and ductile iron pipeline girth weld joints.

- Fitting: For protection against external corroiosn of buried immersed or above ground carbon steel ,alloyed steel and ductile iron pipe fittings such as elbow,bends,tees,reduces,flanges,etc

- Pipe coating repair :For repair and rehabilitaion and protection against external corrosion of pipeline coating defects.

- Seams and Joints: For sealing of seams and joints in steel structures.

- Flanges: For protection against external corrosion and shaping of connection flanges,insulation flanges and blind flanges.

- Valves: For protection against externalcorrosion and shaping of valves

- Irregular shaped parts: For protection against external corrosion and shaping of manhole covers,bolts and nuts etc.

- Cad welds: For protection against external corrosion of welded CP-wire connections on underground pipelines and underground steel structures protected by CP.

- Pipe coating repairs: For protection against external corrosion and as filler for pipeline coating defects of e.g. 3LPE coated ,prior to application of consecutive mechanical protective coating.

Viscoelastic Body Adhesive Tape

Item | Test method | Performance |

color | Visual estimation | green |

thickness | ASTM D1000 | ≥1.8mm |

application temperature range | ----- | -45~70°C |

Specific Insulation Resistance | EN 12068 | ≥108Ω.m2 |

Dielectric strength | DIN 53481 | ≥10kv/mm |

| peel strength @ (23 ℃) to PE to Steel to FBE |

ISO 21809-3 | 4N/cm 5N/cm 6N/cm |

Lap Shear @ 23℃ | ISO 21809-3 | 0.04N/mm2 |

Water Absorption | ASTM D 570 | 0.03% |

Impact Resistance | EN 12068 | > 15J |

Cathodic Disbandment | EN 12068 | ≤20 mm-rad |

Drip Resistance @85 ℃ for 72 hours | ----- | No dripping |

Chemical Resistance 10% HCL,10%Na OH, 3%NaCL for 90 days | ----- | Pass |

Hot water immersion @60℃ for 120 days | ---- | Pass |

Packaging :

Commonly use carton:

Shipping :

Container Specification :

| Container Specification | Length*Width*High(m) | Weight (Ton) | Volume (m²) |

| 20GP | Inside: 5.898×2.352×2.385 Outside: 6.058×2.438×2.591 | 17.5 | 24-26 |

| 40GP | Inside: 12.032×2.352×2.385 Outside: 12.192×2.438×2.591 | 22 | 54 |

Jining Xunda Pipe Coating Materials Co.,Ltd , a joint -stock enterprise, possessing a gross investment RMB 42 million, registered capital of RMB 20 million,the manufacturer of anti-corrosion and waterproof coating materials for petrochemical,Oil,Gas and Water underground, underwater and overhead pipelines transport system, are widely used for electricity, chemicals, construction.

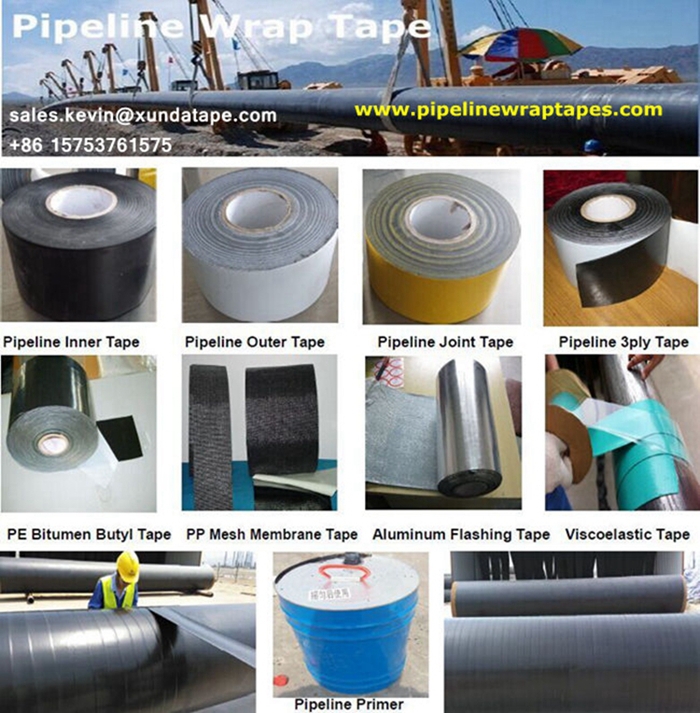

Our main anti-corrosion products : Polyethylene Self Adhesive Tape, Polyethylene Outer Protection Tape, Polyethylene Joint Repair Tape, Polyethylene Double Side Wrap Tape, Polypropylene Mesh Membrane Tape, Polypropylene Waterproof Tape, Aluminum Foil Waterproof Tape, Viscoelastic Body Adhesive Tape, Heat Shrinkable Tape, Heat Shrinkable Sleeve ,Petrolatum Tape etc.

We have got DVGW,AWWA,ASTM,SGS certificates and test report, also the sole factory in China passed DVGW, AWWA test. We were approved ISO 9001,ISO 14001 and OHSAS 18001. XUNDA tapes can meet ASTM D1000, DIN EN12068, 30672,AWWA C209, 214 , IGS and other international standards.

Our major market including 80 countries, widely distributed in South Asia,Southeast Asia, the Middle East, Africa, Central Asia, West Asia, Europe, Eastern Europe, South America, Australia.

Company overview

- Providing OEM, OBM, ODM

- Oil, Gas and Water Transmission pipeline market

- Oil and Gas distribution and utility markets

- New pipeline construction markets

- Rehabilitation and Reconditioning market

- Offshore Industry

- Manufacture of conventional and specialty Polyethylene, Polypropylene and Polymeric Alloys and coating

systems for pipe corrosion protection.

- Manufactures PE coatings systems for applications for New Pipe Construction and Rehabilitation and

Reconditioning

- Approved to ISO 9001 and to other good manufacturing and technical standards and norms governed

within the energy and pipeline industry.

- 15 years of pipeline coating experience

- Global presence in oil, gas and water industries

- Innovative coatings, high temperature systems and niche coatings with first quality products

- Multiple coating systems to meet end-user applications and requirements

- ISO,AWWA,DVGW,SGS approved manufacturing protocol

- Technology/R&D programs for new products and new processes

- Proven long-term performance and corrosion protection on operating pipelines

- Easy of application, consistent application and lower costs

- Compatible with traditional and current corrosion coatings

- Just-in-Time delivery on a global basis

- Achieving and exceeding Client requirements for products, packaging and shipment expectations

- Meetings all International and In-Country transportation requirements

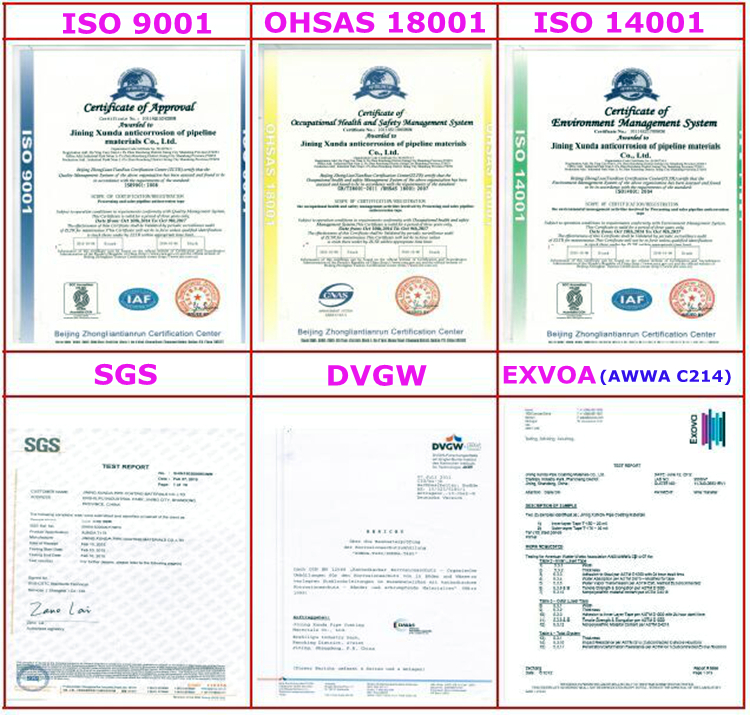

Our Pipe Wrap Tape certificate:

1. ISO 9001

2. OHSAS 18001

3. ISO 14001

4. SGS

5. DVGW

6. EXVOA - AWWA C214

7. SINOPEC : China Petro-Chemical Corporation Supplier

8. CNPC: China National Petroleum Corporation Supplier

9. CNOOC : China National Offshore Oil Corporation Supplier

1. What is the payment terms.

T/T (Telegraphic Transfer) , L/C at sight,Western Union

2. What is the delivery time of the tape.

Usually , 7 days after payment, but it will cost more time when a large order made.

3. Whether the sample is free or not.

The sample will be free with one patch or a small roll . It should paid when you ask for large quantity samples.

4.What is your qualification.

We are the manufacturer of anticorrosion tape for 18 years. All our products are ISO,DVGW, SGS,

AWWA approved.we are the membership supplier of SINOPEC, CNOOC ,CNPC. Our products had

exported to more than 80 countries.

5. What is your after-sales service.

1). Quality reponse

2). Providing technical proposanl and feld application training

3).Product replacement if it is the quality problem.

Product Categories : Viscoelastic Pipe Coating > Visco Elastic Tape