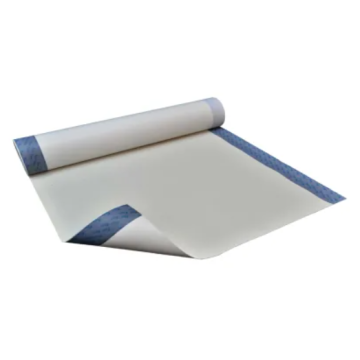

MBP Pro Waterproof Material

Product Description

Product description:

MBP Pro waterproofing membrane is a special composite sheet comprised of a robust HDPE or TPO layer, a pressure-sensitive Adhesive layer and a special protective layer applied to protect adhesive layer from external factors. Thanks to this feature, it is a professional waterproofing membrane in the composite structure which does not allow water to move between the reinforced concrete structure and membrane. The membrane has two sided bonding overlaps.

Material thickness:

2 mm, 1.7 mm, 1.5 mm and 1.2 mm

Packing:

1 x 20 mt in rolls and 2 x 20 mt

System Components:

• MBP Pro 2.00 mm, 1.7 mm, 1.5 mm and 1.2 mm membrane

• MBP Pro Double Sided Tape (sealed double-sided adhesive tape for tip finishing joints)

• MBP Pro Sanded Tape (mineral sand-coated tape that adheres to the structural concrete that is sealed on one side and on top of it)

Application Range

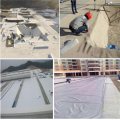

Applied either horizontally to smoothly prepared concrete substrate and compacted earth or crushed stone substrate; or vertically to permanent formwork. Concrete is then cast directly against the adhesive side of the membranes.

MBP Pro Membrane is used for the waterproofing of exterior basement walls, foundations, floor plates, etc.The same product is suitable for vertical and horizontal areas. MBP Membrane is usable against pressurized water.

·Waterproofing to basements of industrial and civil engineering.

·Pre-applied waterproofing system for walls, tunnels and subways.

Approvals / Tests:

• CE Certificate No: 1023-CRP-0699 F / 2015 EN 13967 Flexible waterproofing membranes

• Methane / Radon Gas Test Report ASTM-D1434

• Impermeability Test Report Under Hydrostatic Pressure DIN-16726-2011-01

• Water Vapor Transmission Rate Test Report ASTM-E96

• Water Absorption Test Report ASTM-D570

• Elasticity Break Elongation Tensile Strength Test Report ASTM-D412

• Puncture Resistance Test Report ASTM-D4833 and ASTM-E154

• Concrete Peel Resistance and Flexibility at Low Temperature Test Report ASTM-D1970 / ASTM-D903

Application Method:

The surface where MBP Pro is to be applied must be solid and smooth. The application surface may be damp, but no puddles. In order to prevent damage to the membrane, the application surface must be smooth and clean. Large openings and voids should be filled using materials with the required strength.

To ensure good adhesion, the joints must be tightened with a roller. Roll finish edges should be taped with MBP Double Tape in corner and piece combinations. In the production of single face curtains, it is necessary to create a smooth bottom surface without spaces.

Suitable Surfaces:

• Concrete

• Smooth Mold Surfaces (Temporary or Permanent)

• Rigid thermal insulation

• Soil

Benefits

·Highly flexible ·Perfect bonding to concrete

.Granular coating ·Weather resistant

·Pressure sensitive adhesive ·Methane barrier

·Continuous thickness ·UV-resistant for>60 days

. Simple installation ·Trafficable

· Watertight ·Crack-bridging

· Highly chemical resistant ·Not harmful for groundwater

Installation Guidance

Application-Preparation of the surface

The surface must be sound, even, stable and clean. The substrate to be coated should not have protrusions, gaps, joints or voids greater than 10 mm. To prevent movements of penetrations such as pipe penetrations for water and electricity during concrete and membrane installation, they have to be fixed and stabilized. Damaged concrete should be renovated with MBP Multi Mortar first. Sharp edges have to be removed first.

Material- horizontal application

MBP Membrane must be placed with the granular adhesive coating layer upwards and the white layer fa the substrate.

The overlapping between the membranes is 75 mm. Before removing the silicone foil(of the overlapping area) ensure that the membranes overlapping edge is positioned correctly. Ensure the back side of each subsequent roll s clean prior to overlapping.

Then start removing of plastic film to bond the membranes together. Use a heavy roller to ensure a complete perfect bonding between the membranes. Then go ahead with removing of plastic film and press membranes together.

Material-vertical application

MBP Membrane must be fixed mechanically to the substrate by using fixing tools. These fixings must have a low profile head so that the membrane won't be damaged from the fixings.

The overlapping between the membranes is 75 mm. Before removing the plastic film (on the overlapping area)ensure that the membranes overlapping edge is positioned correctly. Ensure the back side of each subsequent roll is clean prior to overlapping.

Then start removing of plastic film to bond the membranes together. Use a heavy roller to ensure a complete perfect bonding between the membranes. Then go ahead with removing of plastic film and press membranes together.

Repairs before concrete placement

In case of damaging the MBP Membrane during installation of formwork and reinforcement steel placement it is necessary to repair prior pouring of concrete.

Pouring of concrete

Ensure that all overlapping areas are sealed and the foil is removed in that area. Do not damage the membrane during pouring of concrete.

Formwork removal

It is very important not to remove formwork until the concrete has sufficient compressive strength to develop the required adhesion with MBP Membrane. Too early removal of all formworks can lead to a displacement of MBP Membrane and or concrete damage. A minimum concrete compressive strength of 10 N/mm2 recommended prior removing formwork.

Disclaimer

The information complies with the current state of development. There is no claim for completeness. A professional and therefore successful processing of the products is not within our responsibility. We accept a warranty only for the quality of the products, but not for processing. It is the responsibility of the user to evaluate the suitability of our products for its purpose. Preliminary tests are recommended.

MBP Pro Technical Data Sheet - Revision Date 01/2019

| No. | Characteristics | Performance | Test Standard |

| 1 | Max. Tensile Force | ≥ 650 N/50mm | EN 12311-2:2013 |

| 2 | Elongation at rapture | ≥ %400 | EN 12311-2:2013 |

| 3 | Tear strength | ≥ 500 N | EN 12310-1:2001 |

| 4 | Reaction to fire | Class E | EN 13501-1+A1:2009 |

| 5 | Static loading | ≤20kg | EN 12730:2001 |

| 6 | Joint strenght | ≥ 600 N/50mm | EN 12317-2:2010 |

| 7 | Impact resistance | ≤700mm | EN 12691:2006(Method A) |

| 8 | Water tightness | Pass (24h/60kPa) | EN 1928:2000 |

| 9 | Durability water tightness after artificial ageing | Pass | EN 1298:2000 EN 1926:2001 |

| 10 | Durability water tightness against chemicals | Pass | EN 1928:2000 EN 1847:2009 |

Product Categories : Construction Material And Equipment > Water Proof Material