Butyl seal putty for filling gap and irregular contour

Product Description

Butyl seal putty for filling gap and irregular contour

I .Description

Butyl seal putty is a VOC free, cold applied ,flexible ,non-hardening compound that is designed to fill gaps and irregualr contours prior to the application of Xunda tape.The moulding compound is specially formulated with inert organic fillers fillers in a saturated hydrocarbon polyer base.

Moulding compound comes in small cartons to allow the compound to be applied to the substrate and contoured with a gloved hand.

II.Substrate compatibility:

Steel, stainless steel ,ductile iron,other metals ,FBE,PE ,PP,concrete

III. Use:

Ideal for mechanical couplings,nuts,bolts,bell and spigot joint ,saddle tees,leak clamps and any area that a smoother more contoured coating surface is preferred prior to application of Xunda tapes.

No primer is needed prior to application.

SSPC SP-2 hand tool cleaning,SSPC SP-3 power tool cleaning or SSPC SP-6/NACE No.3 commercial blast cleaning.

IV. Physical Properties:

| Property | Value | Test Method |

| Color | Black | |

| VOC content | 0g/L | |

| Specific Gravity | 1.9g/ml | ASTM D1475 |

| Cone Penetration | 150d.mm | ASTM D937 |

| Storage @23℃ | No hardening should occur | |

| Application Temperature Range | 5 ℃ to 50 ℃ | |

| Service Temperature Range | up to 70 ℃ |

Packaging :

Shipping :

Container Specification :

| Container Specification | Length*Width*High(m) | Weight (Ton) |

| 20GP | Inside: 5.898×2.352×2.385 Outside: 6.058×2.438×2.591 | 17 |

| 40GP | Inside: 12.032×2.352×2.385 Outside: 12.192×2.438×2.591 | 22 |

Copy to browser:

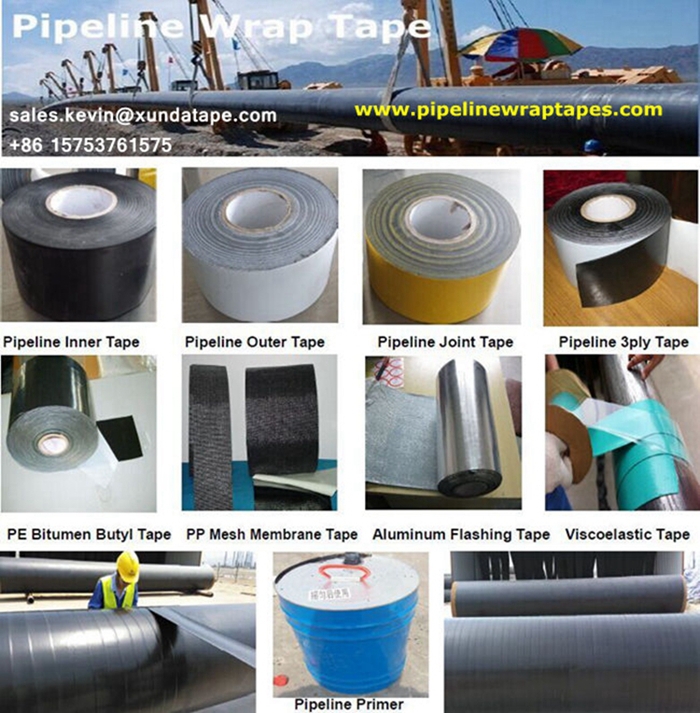

Jining Xunda Pipe Coating Materials Co.,Ltd , a joint -stock enterprise, possessing a gross investment RMB 42 million, registered capital of RMB 20 million,the manufacturer of anti-corrosion and waterproof coating materials for petrochemical,Oil,Gas and Water underground, underwater and overhead pipelines transport system, are widely used for electricity, chemicals, construction.

Our main anti-corrosion products : Polyethylene Self Adhesive Tape, Polyethylene Outer Protection Tape, Polyethylene Joint Repair Tape, Polyethylene Double Side Wrap Tape, Polypropylene Mesh Membrane Tape, Polypropylene Waterproof Tape, Aluminum Foil Waterproof Tape, Viscoelastic Body Adhesive Tape, Heat Shrinkable Tape, Heat Shrinkable Sleeve ,Petrolatum Tape etc.

We have got DVGW,AWWA,ASTM,SGS certificates and test report, also the sole factory in China passed DVGW, AWWA test. We were approved ISO 9001,ISO 14001 and OHSAS 18001. XUNDA tapes can meet ASTM D1000, DIN EN12068, 30672,AWWA C209, 214 , IGS and other international standards.

Our major market including 80 countries, widely distributed in South Asia,Southeast Asia, the Middle East, Africa, Central Asia, West Asia, Europe, Eastern Europe, South America, Australia.

Company overview

- Providing OEM, OBM, ODM

- Oil, Gas and Water Transmission pipeline market

- Oil and Gas distribution and utility markets

- New pipeline construction markets

- Rehabilitation and Reconditioning market

- Offshore Industry

- Manufacture of conventional and specialty Polyethylene, Polypropylene and Polymeric Alloys and coating

systems for pipe corrosion protection.

- Manufactures PE coatings systems for applications for New Pipe Construction and Rehabilitation and

Reconditioning

- Approved to ISO 9001 and to other good manufacturing and technical standards and norms governed

within the energy and pipeline industry.

- 15 years of pipeline coating experience

- Global presence in oil, gas and water industries

- Innovative coatings, high temperature systems and niche coatings with first quality products

- Multiple coating systems to meet end-user applications and requirements

- ISO,AWWA,DVGW,SGS approved manufacturing protocol

- Technology/R&D programs for new products and new processes

- Proven long-term performance and corrosion protection on operating pipelines

- Easy of application, consistent application and lower costs

- Compatible with traditional and current corrosion coatings

- Just-in-Time delivery on a global basis

- Achieving and exceeding Client requirements for products, packaging and shipment expectations

- Meetings all International and In-Country transportation requirements

1) Steel pipe pretreatment

1.1 Keeping the pipe external surface clean and dry.Remove the dust, oil, welding slag, burrs,

grease an dirt on pipe surface.

1.2 Pipe surface prepared up-to a level of Sa 2 or 2 ½ or St 2/st by sand blasting.

1.3 After the precleaning operations, the pipe surface not smoothwhich may sharp the pipe coating

should be burnished , the abrasive dust attached on the pipe surface should also be

cleaned clearly.

1.4 If flash rusting occurs, the surfaces must be re-cleaned by blasting as above.

2) Coating &Wrapping application

2.1 Coating &wrapping application consist of primer application, inner tape coating ,outer tape

coating .

2.2 weather condition

2.2.1 When the wind&sand was strongly, when the sand and dust covered on the surface of pipe,

primer , tape etc., should not be brushing primer and wrapping the tape if there is

no reliable preventive measures.

2.2.2 When air humidity is greater than 80%,or when the pipe surface is wet from any precipitation,

should not be brushing primer and wrapping tape.

3) Brushing primer

3.1 The brushing time should be control within 6 hours between the pipe surface treatment and

brush primer.During brush primer, pipe surface should be free from damp and

pollution. If the pipe surface rust return, should be re-pre-cleaned.

3.2 The primer should be mixed evenly in the container before brushing.

3.3 The primer should be applied uniformly, without any sags, floods, runs, drips, bare spot and

over spray, such as leakage brush, clot, streaming. The primer coat DFT shall not be less

than 25-50micron (1-2mils)

3.4 After the primer dried, then wrapping the tape(It usually takes 3to 5 minutes.).

3.5 Consumption:

machine applicationapprox. 0,1 litre/m²

hand applicationapprox. 0,2 litre/m²

4) Wrap tape application

4.1 Wrap tape application consists of hand application and machine application.

4.2 The tape applied temperature must be above 5 degrees,the coating construction temperature

shall be more than -5 degrees as better .

4.3 The tape shall be spirally applied ,minimum overlap shall not be less than 50%.

4.4 When a new roll of tape started ,the ends shall be located to ensure the continuity of wrap tape

using the same method of application.

4.5 Outer tape applied method is the same as above.

5.Cutbacks

Cutbacks shall be a minimum 6inches(150mm) from the ends of each pipe.The cutbacks may be

tapered or straight edge for the total thickness of the coating.

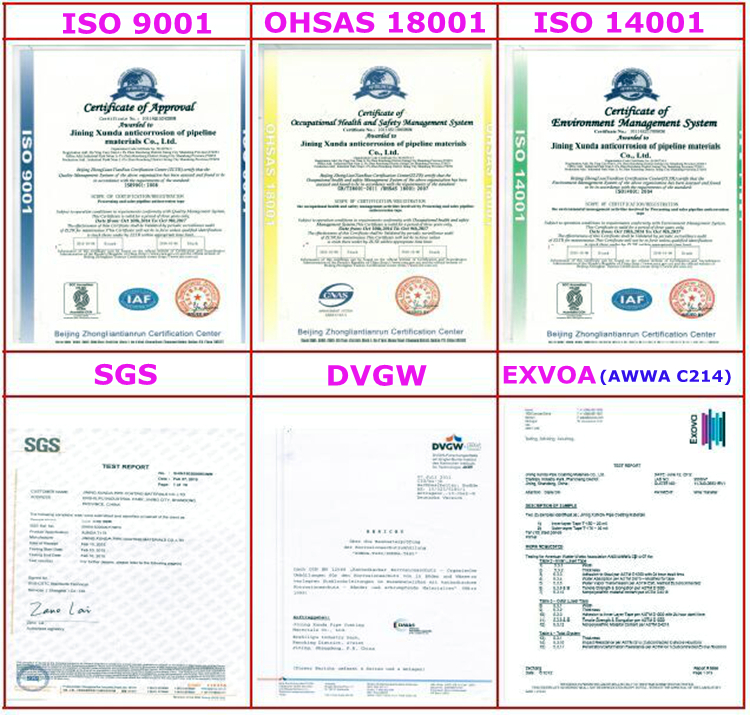

Our Pipe Wrap Tape certificate:

1. ISO 9001

2. OHSAS 18001

3. ISO 14001

4. SGS

5. DVGW

6. EXVOA - AWWA C214

7. SINOPEC : China Petro-Chemical Corporation Supplier

8. CNPC: China National Petroleum Corporation Supplier

9. CNOOC : China National Offshore Oil Corporation Supplier

1. What is the payment terms.

T/T (Telegraphic Transfer) , L/C at sight,Western Union

2. What is the delivery time of the tape.

Usually , 7 days after payment, but it will cost more time when a large order made.

3. Whether the sample is free or not.

The sample will be free with one patch or a small roll . It should paid when you ask for large quantity samples.

4.What is your qualification.

We are the manufacturer of anticorrosion tape for 18 years. All our products are ISO,DVGW,SGS,

AWWA approved.we are the membership supplier of SINOPEC, CNOOC ,CNPC. Our products had

exported to more than 80 countries.

5. What is your after-sales service.

1). Quality reponse

2). Providing technical proposanl and feld application training

3).Product replacement if it is the quality problem.

Product Categories : Sealing and Waterproof Tape > Butyl Putty Tape