manufacture in China Oil petrolatum tape

Product Description

manufacture in China Oil Petrolatum Tape

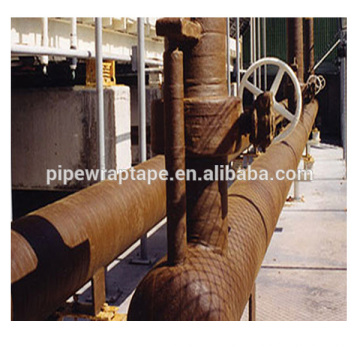

The petrolatum Coating System is designed for Corrosion Protection of buried or exposed or marine pipes rods, cables, valves and metal fittings, tanks. it consist of petrolatum tape, petrolatum mastic, Petrolatum Primer, outer tape.

Petrolatum Tape

Petrolatum tape is a non-hardening and non-cracking corrosion protection wrap . It is highly resistant to mineral acids, alkalis, salts and micro-organisms and highly impermeable to water vapor and gases. Used for the protection of buried or exposed pipes, rods, cable, valves and metal fittings from corrosion.

It is composed of a non woven fibre fabric coated with a neutral compound based on saturated petrolatum and inert siliceous fillers.

Petrolatum Primer

Petrolatum primer is a tacky Adhesive primer for use with petrolatum tape .High melting point petrolatum in hydrocarbon solvent . Petrolatum primer is a semi solid paste for brush application.

Petrolatum Mastic

Petrolatum mastic is a cold applied mastic for sealing and filling the pipeline valve ,flange etc.

It suitable for application in a wide range of climatic conditions. It is used for moulding around irregular profiles such as flange ,valve,joint to provide a contour that suitable for wrapping the petrolatum tape. It contains inert siliceous fillers and vegetable fibres.

Outer Tape

The outer tape is designed for protection of petrolatum tape, it should applied after petrolatum tape.

P27: Solid content 27%.

UV resistance

Suitable to irregular shapes and profiles

It can be applied to cold ,wet surfaces.

It can be applied above and below ground.

Excellent resistance water, acid, salts or soil organics

Property | Typical Value |

Tensile Strength | >40N/cm |

Elongation | 15% |

Breakdown Voltage(55% overlap) | >18KV |

Chemical Resistance (7days ,10% Hydrochloric Acid) | Excellent |

Chemical Resistance (7days ,20% Sodium Chloride) | Excellent |

Chemical Resistance (7days ,10% Potassium Chloride) | Excellent |

Color | Brown,Light Yellow |

Thickness | 1.2mm |

Width | 50mm,100mm,150mm |

Length | 10m |

Weight | 1.5kg/m2 |

| Temperature Range Application Service |

-30℃ - 70 ℃ -5 ℃- 45 ℃ |

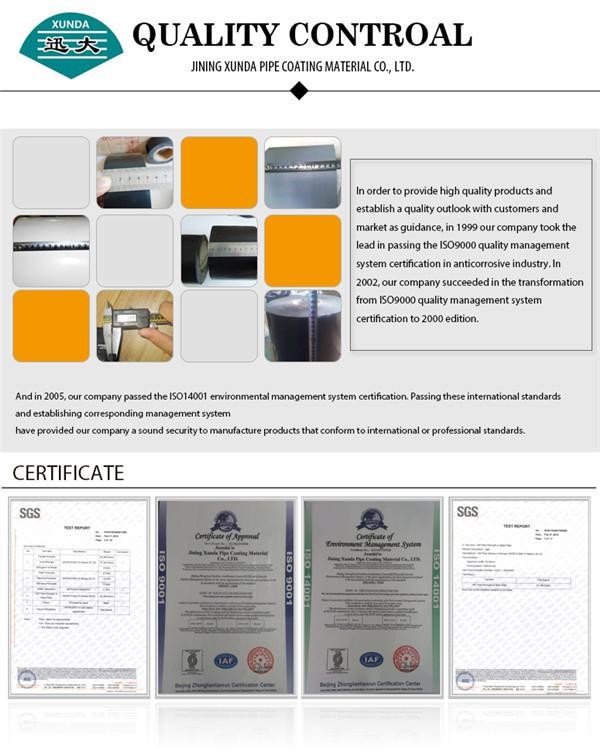

Our Pipe Wrap Tape certificate:

1. ISO 9001

2. OHSAS 18001

3. ISO 14001

4. SGS

5. DVGW

6. EXVOA - AWWA C214

7. SINOPEC : China Petro-Chemical Corporation Supplier

8. CNPC: China National Petroleum Corporation Supplier

9. CNOOC : China National Offshore Oil Corporation Supplier

Shipping:

By sea from Qingdao , China

Shipping :

Container Specification :

| Container Specification | Length*Width*High(m) | Weight (Ton) | Volume (m²) |

| 20GP | Inside: 5.898×2.352×2.385 Outside: 6.058×2.438×2.591 | 17.5 | 24-26 |

| 40GP | Inside: 12.032×2.352×2.385 Outside: 12.192×2.438×2.591 | 22 | 54 |

| 40HQ | Inside: 12.032×2.352×2.385 Outside: 12.192×2.438×2.591 | 22 | 68 |

| 45HQ | Inside : 13.556×2.352×2.698 Outside: 13.716×2.438×2.896 | 29 | 78 |

1) Steel pipe pretreatment

1.1 Keeping the pipe external surface clean and dry.Remove the dust, oil, welding slag, burrs, grease and dirt on pipe surface.

1.2 Pipe surface prepared up-to a level of Sa 2 or 2 ½ or St 2/st by sand blasting.

1.3 After the precleaning operations, the pipe surface not smoothwhich may sharp the pipe coating should be burnished , the abrasive dust attached on the pipe surface should also be cleaned clearly.

1.4 If flash rusting occurs, the surfaces must be re-cleaned by blasting as above.

2) Coating &Wrapping application

2.1 Coating &wrapping application consist of primer application, inner tape coating ,outer tape coating .

2.2 weather condition

2.2.1 When the wind&sand was strongly, when the sand and dust covered on the surface of pipe, primer ,

tape etc., should not be brushing primer and wrapping the tape if there is no reliable

preventive measures.

2.2.2 When air humidity is greater than 80%,or when the pipe surface is wet from any precipitation, should not be brushing primer and wrapping tape.

3) Brushing primer

3.1 The brushing time should be control within 6 hours between the pipe surface treatment and brush primer During brush primer, pipe surface should be free from damp and pollution. If the pipe surface

rust return, should be re-pre-cleaned.

3.2 The primer should be mixed evenly in the container before brushing.

3.3 The primer should be applied uniformly, without any sags, floods, runs, drips, bare spot and over spray,

such as leakage brush, clot, streaming. The primer coat DFT shall not be less than 25-50micron (1-2mils)

3.4 After the primer dried, then wrapping the tape(It usually takes 3to 5 minutes.).

3.5 Consumption:

machine applicationapprox. 0,1 litre/m²

hand applicationapprox. 0,2 litre/m²

4) Wrap tape application

4.1 Wrap tape application consists of hand application and machine application.

4.2 The tape applied temperature must be above 5 degrees,the coating construction temperature shall be

more than -5 degrees as better .

4.3 The tape shall be spirally applied ,minimum overlap shall not be less than 50%.

4.4 When a new roll of tape started ,the ends shall be located to ensure the continuity of wrap tape using the

same method of application.

4.5 Outer tape applied method is the same as above.

5.Cutbacks

Cutbacks shall be a minimum 6inches(150mm) from the ends of each pipe.The cutbacks may be tapered

or straight edge for the total thickness of the coating.

Jining Xunda Pipe Coating Material Co., Ltd. is the largest manufacturer of anti-corrosion coating materials in China.

We are a global company supplying Polyethylene Coating Systems for anti-corrosion in the oil, gas and water pipeline construction industry for both onshore and

offshore applications.

We are a manufacturer of standard and special products. With high-quality anti-corrosion systems, we are providing anti-corrosion solutions for oil pipelines, natural gas, chemicals and water transmission and distribution pipelines.

We are a global supplier of PE corrosion systems for metallic pipelines.

We serve:

Oil, gas and water transmission pipeline markets

Oil and gas distribution and utility markets

New pipeline construction markets

Rehabilitation and reconditioning markets

Offshore industry

Refinery and petrochemical plant industry

We manufacture polyethylene coating by utilizing butyl based elastomeric adhesives, Polyethylene

films and liquid adhesives for corrosion protection of steel pipes

TRADE TERMS:

1 Payment: 30% T/T DEPOSIT PAYMENT IN ADVANCE, BALANCE AGAINST COPY OF B/L,

WESTERN UNION, ESCROW, L/C.

2 Production Lead Time: 10 - 15 DAYS AFTER DEPOSIT PAYMENT.

3 Shipping Methods: OCEAN FREIGHT / AIR FLIGHT /COURIER PRESS

4 FOB Shipping port: QINGDAO, SHANGHAI ,OTHER PORTS, MAINLAND CHINA.

5 If you want to deal with EXW/CIF/CNF term instead of FOB, please specify. Otherwise, FOB price will be quoted under inquiry.

OUR SERVICE:

- Your inquiry related to our product & price will be replied within 24hours.

- Well-trained & experienced staffs are to answer all your inquiries in English of course.

- Working time: 8:30am - 6:00pm, Monday to Saturday (UTC+8).

- OEM & ODM projects are highly welcomed. We have strong R&D team here to help.

- Your business relationship with us will be confidential to any third party.

- Good after-sale service offered, please get back if you got question.

Transportation and Storage

1) Keep it away from insolation, rain, or pressing.

2) If it has been stored or transported in the temperature below 5degree, it has to be put in the place at about 20degree for 48hours before it is installed.

3) The storage time is 12 months. It should be kept in a cool place at5~30degree, <75degree, away from heat or open fire.

1. What is the payment terms.

T/T (Telegraphic Transfer) , L/C at sight,Western Union

2. What is the delivery time of the tape.

Usually , 7 days after payment, but it will cost more time when a large order made.

3. Whether the sample is free or not.

The sample will be free with one patch or a small roll . It should paid when you ask for large quantity samples.

4.What is your qualification.

We are the manufacturer of anticorrosion tape for 18 years. All our products are ISO,DVGW, SGS,AWWA approved.we are the membership supplier of SINOPEC, CNOOC ,CNPC. Our products had exported to more than 80 countries.

5. What is your after-sales service.

1). Quality reponse

2). Providing technical proposanl and feld application training

3).Product replacement if it is the quality problem.

Want to know more details, please contact us:

Contact :Nancy Song

Skype:nancysong7

whatsapp:008613791713064

008618853777565

wechat(QQ):438391083

Contact us if you need more details on Oil Petrolatum Tape. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Manufacture Petrolatum Tape、Anticorrosion Tape. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Petrolatum Pipe Coating > Petrolatum Tape

Premium Related Products