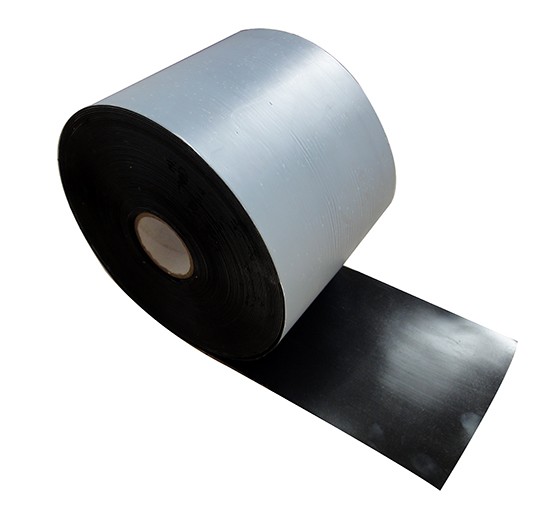

Petrolatum tape waterproof marine tape for pipe anti corrosion

Product Description

Petrolatum Tape waterproof Marine Tape for pipe anti corrosion

I. Description:

Petrolatum tape waterproof marine tape is a non-woven synthetic fabric carrier, fully impregnated with a neutral compound based on saturated petrolatum and inert siliceous fillers.

II. Uses:

Petrolatum tape provided above and below and underwater corrosion protection to pipelines, fittings, tank bases, steel structures and many more.

Our petrolatum tape wrap systems can easily be applied by hand to most surfaces in arctic and tropical temperature environments.

III. Features:

Outstanding long term anti corrosion characteristics

UV resistant

Can be applied to cold, wet, surfaces

Not effected by water, acid, salts or soil organics

Meets AWWA C217 standards

Can be applied above and below ground

Safe and easy to use

IV. Technical Data

Item | Product performance |

Color | Yellow brown |

Insulation voltage | ≥16KV, 55%, overlapped. |

Weight | Average ≥1.45kg/m^2 |

Thickness | Average ≥1.20mm |

Solution resistant to 10% hydrochloric acid (immerged for 7 days) | No abnormal change |

Solution resistant to 10% potassium chloride (immerged for 7 days) | No abnormal change |

Breaking Strength | 200N/50mm min |

Elongation at break | 10% avg |

Water Vapor Permeability | 0.006 per avg |

Operation temp | -5°C to 55°C |

Applicable temp | Normal temp.:-50°C to 75°C, high temp. -50°C to 110°C |

Length | 10m or as customers’ requirement |

Width 50,100,150,200,300 | 50, 100,150,200,300mm or other width |

Package | Plastic package in paper case for case for each coil of tape |

AC external band Product performance parameter

Material | Special self-Adhesive PVC sealing tape |

Color | Black or yellow |

Thickness | ≥0.10 |

Breakage extension rate (%) | ≥100 |

Function | Good flexibility to adhere at overlapping and wound at exterior of oily band corrosion prevention layer tightly against loss of grease to improve mechanical protection intensity and electric insulation |

Package | 41m /coil width 50,100and 150mm in paper case |

|  |

| Pipeline Anti-Corrosion Tape | Mechanical Protection Tape |

|  |

| Polyethylene Bitumen Tape | Viscoelastic Tape |

1. What is the payment terms.

T/T (Telegraphic Transfer) , L/C at sight,Western Union

2. What is the delivery time of the tape.

Usually , 7 days after payment, but it will cost more time when a large order made.

3. Whether the sample is free or not.

The sample will be free with one patch or a small roll . It should paid when you ask for large quantity samples.

4.What is your qualification.

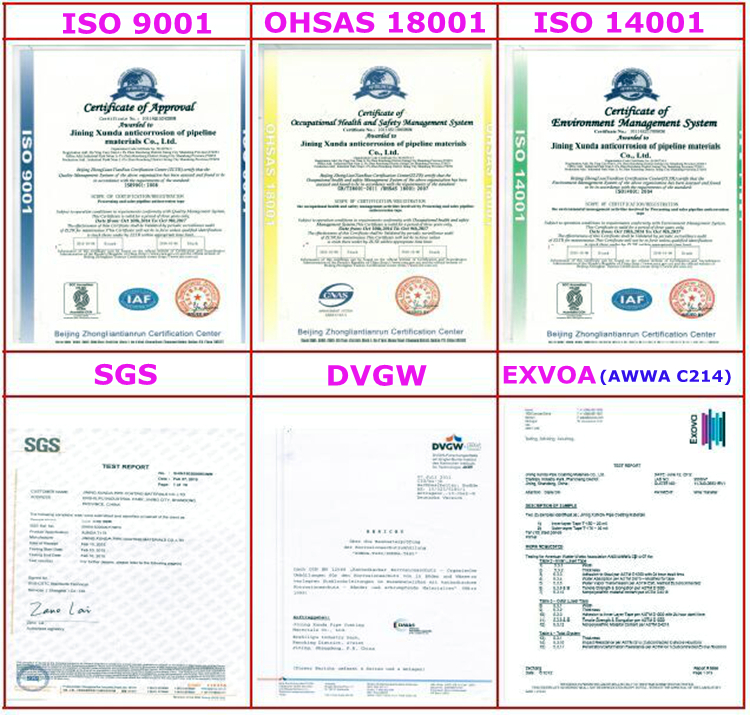

We are the manufacturer of anti-corrosion tape for 18 years. All our products are ISO,DVGW, SGS,

AWWA approved.we are the membership supplier of SINOPEC, CNOOC ,CNPC. Our products had

exported to more than 80 countries.

5. What is your after-sales service.

1). Quality response

2). Providing technical proposal and field application training

3).Product replacement if it is the quality problem.

| Tel | 0086 15753761575 |

| 0086 15753761575 | |

| |

| Website |

|

| zxm_kevin | |

| Skype | zhanxuemeng |

Jining Xunda Pipe Coating Materials Co.,Ltd , a joint -stock enterprise, possessing a gross investment RMB 42 million, registered capital of RMB 20 million,the manufacturer of anti-corrosion and waterproof coating materials for petrochemical,Oil,Gas and Water underground, underwater and overhead pipelines transport system, are widely used for electricity, chemicals, construction.

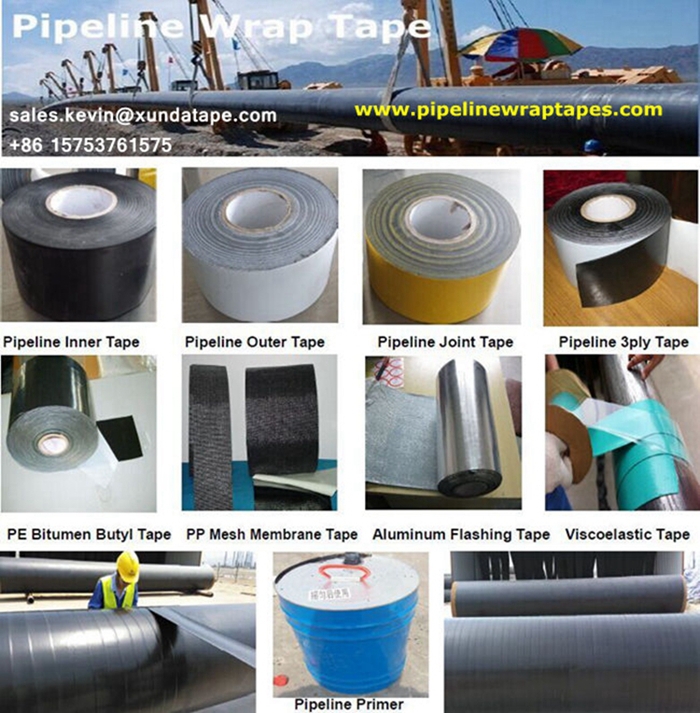

Our main anti-corrosion products : Polyethylene Self Adhesive Tape, Polyethylene Outer Protection Tape, Polyethylene Joint Repair Tape, Polyethylene Double Side Wrap Tape, Polypropylene Mesh Membrane Tape, Polypropylene Waterproof Tape, Aluminum Foil Waterproof Tape, Viscoelastic Body Adhesive Tape, Heat Shrinkable Tape, Heat Shrinkable Sleeve ,Petrolatum Tape etc.

We have got DVGW,AWWA,ASTM,SGS certificates and test report, also the sole factory in China passed DVGW, AWWA test. We were approved ISO 9001,ISO 14001 and OHSAS 18001. XUNDA tapes can meet ASTM D1000, DIN EN12068, 30672,AWWA C209, 214 , IGS and other international standards.

Our major market including 80 countries, widely distributed in South Asia,Southeast Asia, the Middle East, Africa, Central Asia, West Asia, Europe, Eastern Europe, South America, Australia.

Company overview

Packaging :

Commonly use carton:

| Tape Thickness | Tape Size | Carton Size | SQM/CTN(m²) | Quantity/CTN |

| 0.51mm | 0.51mm*200mm*50m | 410cm*210cm*415cm | 40 | 4 |

| 0.51mm*150mm*50m | 420cm*420cm*320cm | 60 | 8 | |

| 0.51mm*100mm*50m | 420cm*420cm*320cm | 60 | 12 | |

| 0.51mm*75mm*50m | 420cm*420cm*320cm | 60 | 16 | |

| 0.51mm*50mm*50m | 420cm*420cm*320cm | 60 | 24 | |

| 0.75mm | 0.75mm*200mm*50m | 410cm*210cm*415cm | 28 | 4 |

| 0.75mm*150mm*50m | 420cm*420cm*320cm | 42 | 8 | |

| 0.75mm*100mm*50m | 420cm*420cm*320cm | 42 | 12 | |

| 0.75mm*75mm*50m | 420cm*420cm*320cm | 42 | 16 | |

| 0.75mm*50mm*50m | 420cm*420cm*320cm | 42 | 24 |

Shipping :

Container Specification :

| Container Specification | Length*Width*High(m) | Weight (Ton) | Volume (m²) |

| 20GP | Inside: 5.898×2.352×2.385 Outside: 6.058×2.438×2.591 | 17.5 | 24-26 |

| 40GP | Inside: 12.032×2.352×2.385 Outside: 12.192×2.438×2.591 | 22 | 54 |

| 40HQ | Inside: 12.032×2.352×2.385 Outside: 12.192×2.438×2.591 | 22 | 68 |

| 45HQ | Inside : 13.556×2.352×2.698 Outside: 13.716×2.438×2.896 | 29 | 78 |

- OEM, OBM, ODM

- Oil, Gas and Water Transmission pipeline market

- Oil and Gas distribution and utility markets

- New pipeline construction markets

- Rehabilitation and Reconditioning market

- Offshore Industry

- Manufacture of conventional and specialty Polyethylene, Polypropylene and Polymeric Alloys and coating

systems for pipe corrosion protection.

- Manufactures PE coatings systems for applications for New Pipe Construction and Rehabilitation and

Reconditioning

- Approved to ISO 9001 and to other good manufacturing and technical standards and norms governed within the energy and pipeline industry.

- 15 years of pipeline coating experience

- Global presence in oil, gas and water industries

- Innovative coatings, high temperature systems and niche coatings with first quality products

- Multiple coating systems to meet end-user applications and requirements

- ISO,AWWA,DVGW,SGS approved manufacturing protocol

- Technology/R&D programs for new products and new processes

- Proven long-term performance and corrosion protection on operating pipelines

- Easy of application, consistent application and lower costs

- Compatible with traditional and current corrosion coatings

- Just-in-Time delivery on a global basis

- Achieving and exceeding Client requirements for products, packaging and shipment expectations

- Meetings all International and In-Country transportation requirements

Our Pipe Wrap Tape certificate:

1. ISO 9001

2. OHSAS 18001

3. ISO 14001

4. SGS

5. DVGW

6. EXVOA - AWWA C214

7. SINOPEC : China Petro-Chemical Corporation Supplier

8. CNPC: China National Petroleum Corporation Supplier

9. CNOOC : China National Offshore Oil Corporation Supplier

Product Categories : Petrolatum Pipe Coating > Petrolatum Tape

Premium Related Products